Quick guide to Inconel 625 Flanges

Inconel is a nickel-chromium alloy 625 is used for its high strength, excellent, fabricability (including joining), and out-standing corrosion resistance. Inconel belongs to the so-called ‘super alloys’ group, which includes especially austenitic nickel-chromium-based alloys. Temperatures in use vary from cryogenic to 1800°F (982°C).

Inconel 625 is made or processed from the stiffening effect of nio-biumon and molybdenum, its nickel-chromium matrix; thus precipitation do not require hardening treatments. This blend of elements is also responsible for excellent resistance to a wide variety of unusually harsh corrosive conditions, as well as high-temperature effects such as oxidation and carburization.

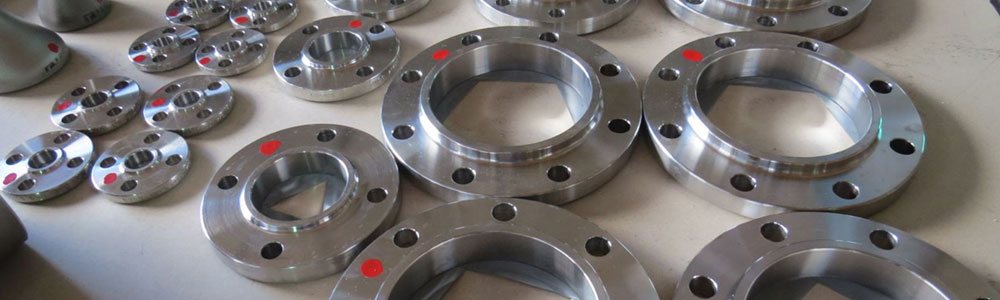

What are Inconel 625 Flanges

A flange is a device used to connect pipes or tube, valves, pumps, and other pieces of equipment to develop a piping structure. It also allows for simple washing, inspection, and alteration. Flanges are welded or screwed. Flanged joints are created by bolting two flanges together with a gasket between them to provide a seal.

One of benefits of Inconel is its potential to be used under severe environments. Such extremes are either high temperatures or heavy pressure. This is because when Inconel is exposed to very high temperatures, it forms a very stable oxide layer, which prevents the metal’s surface from further corrosion.

High temperatures or high pressure are examples of those extremes. This is due to the fact that when Inconel is exposed to very high temperatures, it forms a very durable oxide coat, which protects the metal’s surface from further corrosion.

Inconel flanges have great oxidising and decreasing content of corrosion resistance, making them ideal for a variety of high corrosive applications. It is used in chemical processing applications due to its high resistance to sulphuric acid and hydrochloric acid. Inconel valve flanges are widely found in fuel and water pipelines. It has a longer operating life and is therefore less expensive to maintain.

Inconel 625 flanges are in a variety of configurations, including

- Slip on Flange

- Weld Neck Flanges

- Flanges Reduction

- Socket Weld Flange

- Threaded Flange

- Blind Flanges

- Lap Joint Flanges, and more.

Inconel 625 Flanges are the most prominent and durable corrosion-resistant alloy. After being diluted and partly oxidised, it has a very high corrosive resistance. They are limited, and the fastener are only produced in larger diameters.

Benefits of Inconel 625 Flanges

- Corrosion resistance

- Mechanical properties at high temperatures is excellent

- Suitable for sulphuric and hydrochloric acid environments.

- Outstanding resistance to stress corrosion cracking.

Applications Inconel 625 Flanges

Inconel 625 flanges are used in Chemical industries, Oil and gas factories, gas processing industries, petrochemical industries, food processing industries, sugar industries, power generation industries, and fertiliser industries etc.

Inconel 625 Flanges has a range of applications that has a wide and is widely used for high performances equipment. It is popular to find it in chemical and pressure vessel, pump motor shafts, steam turbine and also in Turbine blades, combustors and seals in oil and gases industries.

When it comes to highly critical uses, 625 Flanges is also one of the key components of nuclear pressurised water reactors.

Inconel 625 Flanges are more durable and robust flanges which are mostly applicable.