Using Inconel and It’s Applications

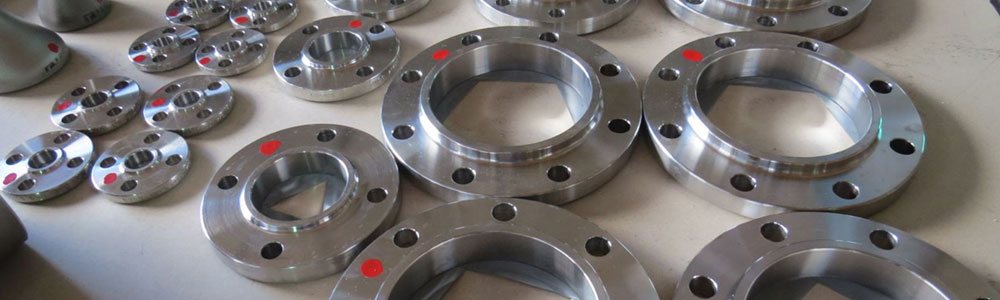

Material like Inconel is designed to withstand harsh production environments. Inconel 625 flanges is a product is stronger than stainless steel, as well as maintaining tensile strength in excess of other steels. Testing strength involves tensile properties, corrosion resistance, and even melting reactions. The tensile strength of Inconel 625 is more than two times that of stainless steel, and it can be used in higher operating temperatures (103-160 Ksi).

Its increased chemical resistance makes it ideal for a wide range of applications involving gases and large temperature variations. Inconel 625 Flanges is made from nickel and chromium and resists oxidation. The aerospace, medical, oil, and gas industries are more likely to use Inconel.

5 major applications of Inconel used in industries

The Use of Heat Treatment

When exposed to extreme temperatures, Inconel maintains sufficient strength to support moderate loads, despite its resistance to extreme temperatures. This gives Inconel an advantage over stainless steel alloys, such as 304, 316, and 330 SS, when it comes to heat treating baskets. In the case of harsh thermal treatments, a basket constructed from an Inconel super-alloy will maintain its form better than one constructed from many stainless steel alloys.

The process of extracting oil and gas

Because Inconel can withstand both high temperatures and oxidation, oil and gas extraction companies prefer it. Super-alloy metals, such as Inconel, are ideal for oil and gas production because they can withstand harsh conditions and corrosive gases.

Super-alloy Inconel 625 is particularly suitable for natural gas processing systems. Inconel 625 has high thermal fatigue strength and enhanced resistance to oxidation, making it a popular choice for use in separating removed fluids and in-line steel pipework.

Jet engines

It is routine for jet engines to operate at extreme temperatures while they are in operation. Combustion chambers and cooling methods are not sufficient to influence Inconel 600’s oxidation resistance and tensile strength. When chemical resistance and extreme temperatures are required, as well as in any application where precious metals would oxidize at high temperatures, Inconel is a great choice.

Rapid Variations in Temperature

Rapid temperature fluctuations are often seen in industrial processes that alternate between operations at high and low temperatures. In general, Inconel alloys have good resistance to oxidation at both high and low temperatures, which allows the basket to be used from low temperatures to very high temperatures.

Usage in Salty water

The outstanding resistance of Inconel to sodium chloride (salt) at a variety of temperatures makes it a popular material for maritime applications. For factories located near the coast or in salty areas, Inconel makes an excellent parts washer material thanks to its anticorrosive characteristics.

Sometimes all the stainless steel is not metallic but are resistant to seawater, knowing these facts should we consider using Inconel is the question.

The benefits of this alloy are primarily related to severe temperatures above 1,000°F, which are not present with grade 316 stainless steel. It would be better to use Inconel than the stainless steel 316 at high temperatures because it’s less prone to oxidation.