Guide to Monel 400: Insights and Advantages

Before getting into the crux of the matter i.e., getting to know the Benefits of using Monel 400 alloy, let us have a brief overview of what exactly does “Monel alloy” means.

Monel Alloys- Description, definition, overview:

Monel Alloy is an amalgamation i.e., a perfect mix of elements such as nickel and copper. Monel alloys were mainly discovered with the sole purpose of defending the components used in various applications from corrosive media.

The most commonly used and worldwide recognized grade of Monel Alloy is the Monel alloy 400.

Monel 400 Threaded Fittings is generally referred to as a binary alloy (Ni-Cu). This grade of Monel alloy was first made in a nickel lab in the early 1900’s. The name Monel has descended from that of the president of the company that discovered the Monel alloy.

Monel 400 alloys contain 60-65% of nickel and copper. Thus, the major components or composing elements are nickel and copper. Besides these, elements including iron, manganese, carbon, silicon, etc. are used.

How does Monel alloy work compare to stainless steel?

When directly compared with the alloying composition, properties, and applications of Stainless Steel grades, Monel alloys are harder to machine and work with as they harden quickly.

In what forms can one find Monel 400 alloy?

Monel 400 alloy just like stainless steel, carbon steel, and other materials and alloys is available in numerous forms including flat bars, shields, rods, round bars, etc. Monel 400 bars have a good strength-to-weight ratio and thus can be used in heavy gauge applications demanding light-weighted components.

Direct comparison between Stainless Steel and Monel 400 Alloy:

- Both stainless steel and Monel alloys can be cold worked with ease.

- SS grades such as 316 have exceptional thermal expansion similar to that of Monel alloy grades. Monel 400 alloys can withstand extreme temperatures above 1000 degrees Celsius.

- The heat tolerance of Monel alloys is two times that of SS grades.

- Monel alloys outshine and outperform stainless steel even in terms of corrosion resistance and high-temperature applications.

Applications and Uses of Monel 400:

- Marine engineering

- Chemical industries

- Valves

- Pumps

- Shafts

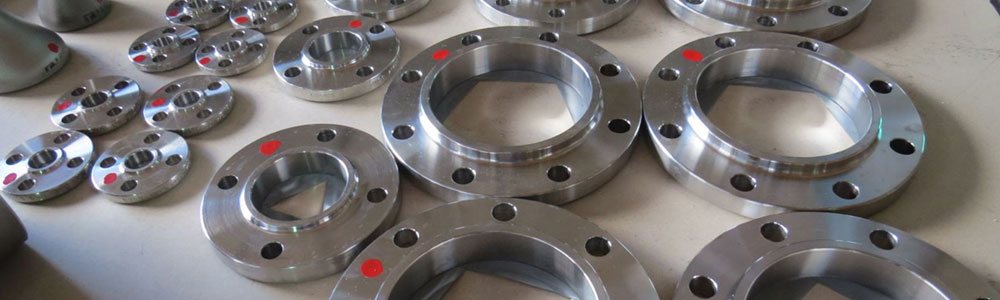

- Fittings

- Fasteners

- Heat exchangers